Background

Superior Concrete Products, operating under the brand ConcreteFence.com, is a Texas-based company specializing in the design, engineering, manufacturing, and installation of precast concrete wall systems. Founded in 1986, the company has grown nationwide, providing strong and attractive fencing solutions for utilities, neighborhoods, businesses, and infrastructure projects. With a commitment to quality craftsmanship, on-time delivery, and sustainable practices, Superior Concrete Products has earned the trust of clients across the United States.

Challenges

Superior Concrete Products manages complex operations across two different sections. While each sector comes with its own complexities, running both simultaneously introduced a unique set of operational challenges. In the past, the company relied on a patchwork of fragmented software systems. Manufacturing, inventory, sales, project management, and accounting each had separate tools, making it difficult to get a clear, real-time view of operations. Tracking and registering expenses on projects was particularly cumbersome, often requiring manual reconciliation and leaving room for errors.

Odoo Decision

The team realized they needed a unified ERP platform capable of managing all facets of their business in one place. After evaluating several options, they selected Odoo. The platform offered the flexibility and comprehensive functionality needed to support both manufacturing and construction operations, eliminating costly and disconnected tools.

With Odoo, Superior Concrete Products now has a smooth integration across departments, optimized expense tracking for projects and a single source of truth for operations. This has not only improved efficiency but also empowered the team to make informed decisions faster, while maintaining quality and reliability.

Ramp Integration

Superior Concrete Products faced significant challenges in registering and automating corporate expenses across their projects. We built the integration for Ramp as their financial solution that allows employees to easily allocate expenses to the correct projects by using Ramp company credit cards. During imports, all transactions are automatically reconciled and linked to the right projects, optimizing their finance operations and reducing manual work.

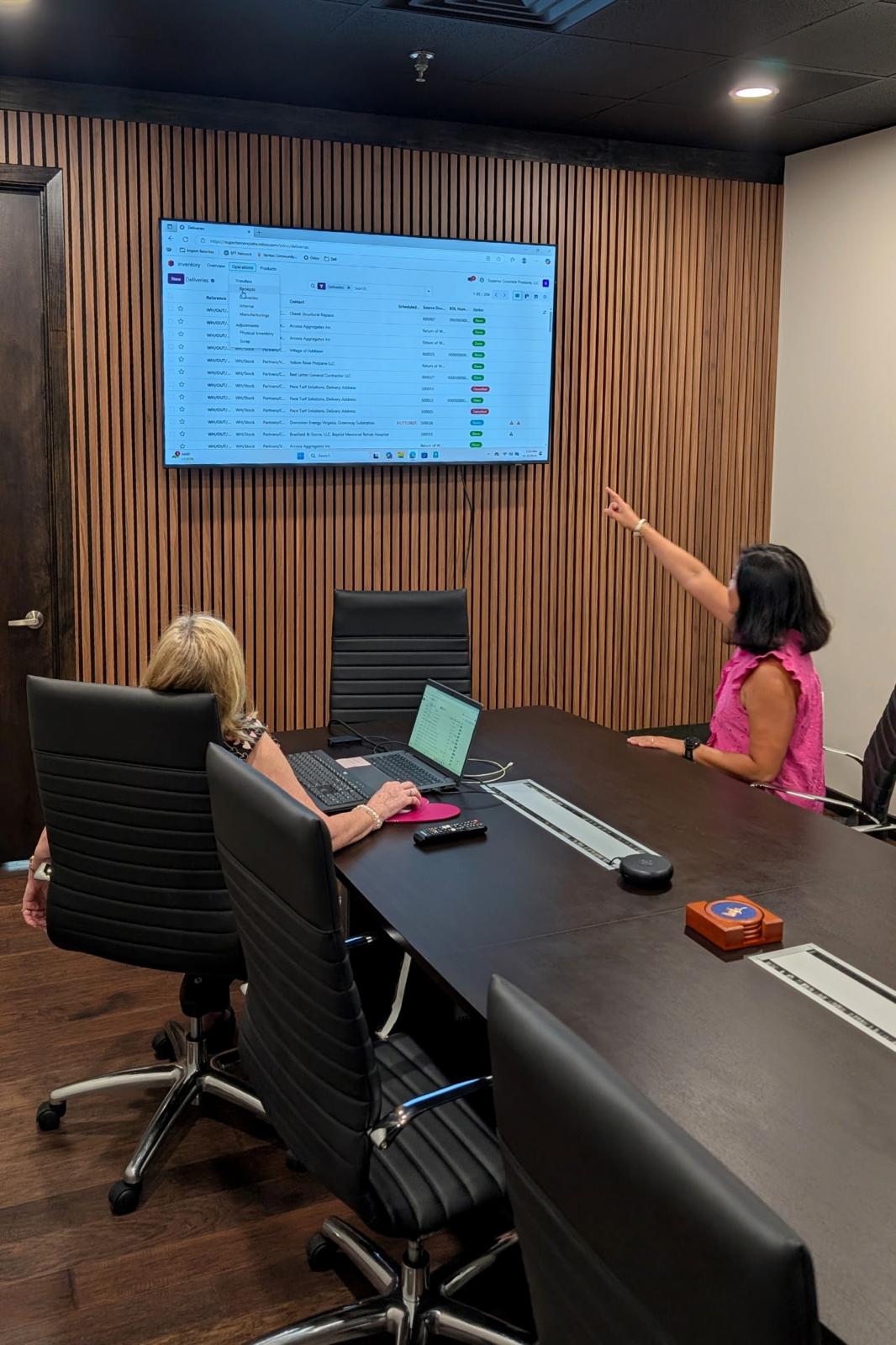

Implementation, Training & Customization

We helped Superior Concrete Products to set up their complete manufacturing workflow & Bill of Materials (BOM) in Odoo. After our training sessions, we built a test environment populated with real example data, allowing the team to confidently test their processes ahead of the Go-Live date.

A month before Go-Live, we imported all products, BOMs, and other static data into the system. Then, in the first week of 2025, we migrated financial data from QuickBooks to Odoo, ensuring a smooth transition and enabling Superior Concrete Products to start the year fully operational on their new platform.

Some of our customizations during this Project:

- Automatic Emailing of Aging Report based on all open projects

- Adjustment on WIP (Work in Progress) Accounting Entry, based on undelivered but completed manufacturing orders

- Calculation tool on Sale Order for the unit price, based on the cost, price, and margin

- Bill of Lading (BOL) solution

- Ramp integration

Questions & Answers with Superior Concrete Products

What were the main factors that made you choose to move to Odoo

for your accounting and ERP?

Our company operates in two

industries, construction and manufacturing, which creates a unique

challenge when it comes to managing systems. In the past, we

struggled with fragmented software that could not handle the

complexity of our dual operations. We needed an ERP platform that

could unify manufacturing, inventory, sales, project management and

accounting in one place. Odoo provided the flexibility and breadth of

functionality to support both sides of our business without forcing

us into costly, siloed solutions.

How do you feel the process of implementing

Odoo and migrating from your old software went?

Like any major system change,

there were growing pains. We had to retrain staff, redesign

procedures, and capture data at a more detailed level than ever

before. However, the payoff was immediate. The difference in accuracy

and process efficiency has been night and day. We’ve eliminated

redundant work, like manually transferring information between

systems, and now have a smoother flow of data across the

organization. It’s been transformational, even if the learning

curve was steep at the start.

What areas of your business were positively

impacted by Odoo?

Every department now touches Odoo

in some way. Sales uses the CRM to track opportunities, inventory

management ensures accurate delivery processes, and accounting gains

visibility without waiting on manual updates. What used to be a

series of disconnected steps is now a connected chain where one

action naturally triggers the next. That kind of visibility has been

critical for both our manufacturing operations and field crews.

Can you quantify or estimate any increases in

efficiencies, productivity, or profitability?

While we didn’t document our

pre-Odoo processes in detail, the consensus across departments is

clear: efficiency has more than doubled. One of the easiest metrics

to highlight is cost savings. By consolidating three separate

software platforms into Odoo, we’ve saved about $20,000 annually in

subscription fees alone. Beyond that, the reduction in manual effort

and time spent switching between systems has unlocked capacity for

our team to focus on higher-value work.

Do you find Odoo is bringing your business together in one “package” and requiring less manual work or spreadsheets?Absolutely. Odoo is the first system we’ve had that truly functions as a unified platform. Instead of relying on spreadsheets or side conversations to confirm data, team members can view, validate, and act on information directly in the system. As we continue to capture more data, we’re now preparing to transition our operational reporting to Odoo as well, which will only deepen that sense of integration.

What are your favorite features or time-savers

in Odoo?

Reporting is hands-down the most

impactful feature. The ability to quickly organize, filter, and

analyze data has transformed how we answer business questions. What

used to take hours in spreadsheets can now be done in minutes. It’s

not just about time savings, it’s about making better decisions

because the information is more reliable and accessible. We’re

excited to see how future versions of Odoo expand these capabilities

even further.

Do you find the ability to access Odoo from

various devices useful in managing your business?

Yes, especially as a construction

business. Our project managers are often on the road or at job sites.

Having a cloud-based ERP that they can access anywhere has been a

game-changer. It keeps our teams connected, ensures orders are

processed without delay, and provides real-time visibility into the

status of projects. It’s eliminated the bottlenecks that used to

happen when information was only available back at the office.

How did DimeSoft play a part in your adoption

and migration to Odoo?

One of the biggest frustrations

we’ve had with vendors in the past is slow response times. DimeSoft

set themselves apart by being responsive and proactive. Whether it

was troubleshooting or answering questions, they addressed issues

quickly so our business didn’t lose momentum. They’ve proven to

be a reliable partner, and we plan to continue working with them on

future Odoo needs.

Has DimeSoft done a good job with software

customization and support?

Yes. We’ve made several

customization requests, and in every case, DimeSoft either found a

solution within Odoo or built one from scratch. A standout example is

our integration with Ramp credit cards, which was a major initiative

for us. DimeSoft made it seamless, and the result has saved countless

hours by automating processes that previously required manual effort.

Their ability to adapt Odoo to our specific needs has been

invaluable.

What areas in Odoo could be improved to better

fit your business?

Reporting is both Odoo’s

greatest strength and its biggest area for improvement. The tools are

far better than what we could build in spreadsheets, but features

like automated report distribution are still lacking. For now, we’ve

worked around this by ensuring all departments have access to the

reporting dashboard, but automatic scheduling and delivery would

significantly improve adoption and efficiency.

How could DimeSoft have done a better job

implementing Odoo?

Overall, we’re very satisfied

with DimeSoft’s work. They’ve been transparent about Odoo’s

limitations and careful to caution us when certain requests might

impact system performance. One area of opportunity would be building

a network of specialized partners. For example, tax compliance,

expense management, or construction-specific needs like

percentage-of-completion reporting are areas where having vetted

partners could enhance the Odoo ecosystem. DimeSoft’s strength is

implementation, and expanding that through partnerships would be a

real value-add for clients like us.